Comprehensive Guide to IEC Environmental Testing

In today’s competitive markets, product reliability is no longer optional—it is expected. Whether for aerospace, automotive, defense, electronics, or consumer goods, your product must withstand the full range of conditions it will face in transport, storage, and operation. This is where IEC environmental testing comes into play.

If you’ve ever wondered:

How can I ensure my product survives real-world conditions?

What is IEC environmental testing?

Which IEC standards should my product comply with?

What equipment do I need to perform these tests?

… then this guide is for you.

What is IEC Environmental Testing?

IEC Environmental Testing refers to a collection of standards published by the International Electrotechnical Commission (IEC). These standards define methods to assess a product’s durability, safety, and performance under simulated environmental conditions—such as vibration, temperature, humidity, mechanical shock, corrosion, and more.

The most widely used series is IEC 60068 — “Environmental Testing,” covering a wide range of test methods to simulate life-cycle stresses.

Why is IEC Environmental Testing Critical?

IEC testing helps answer the question: Will this product perform reliably in the environments where customers will use it?

The tests serve to:

✅ Identify design weaknesses before market release

✅ Validate performance under transportation and operating conditions

✅ Ensure compliance with global safety and quality regulations

✅ Support product certifications and customer confidence

✅ Reduce warranty claims, recalls, and liability risks

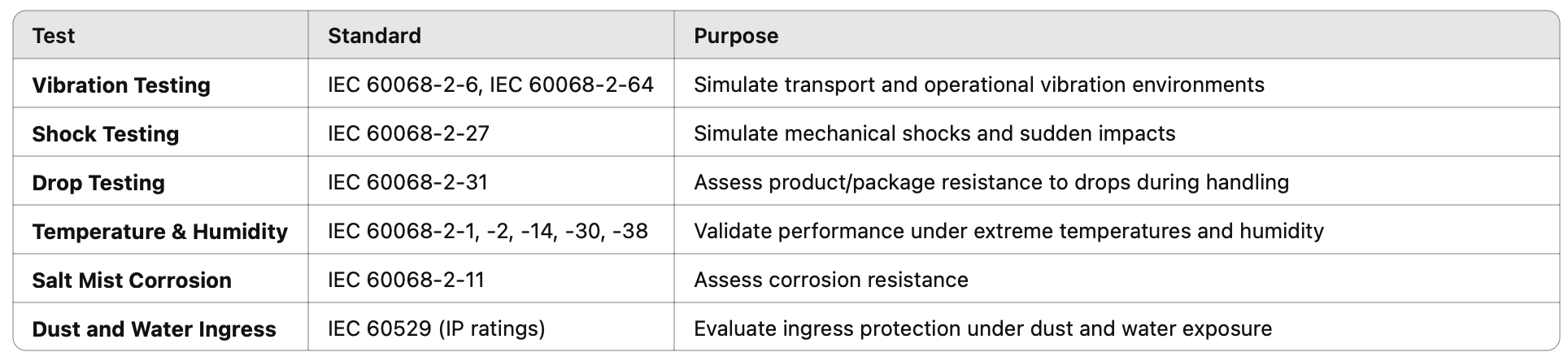

Key IEC Environmental Testing Standards

How is IEC Environmental Testing Performed?

The Testing Process

1️⃣ Define Testing Requirements:

• Identify applicable IEC standards based on product type, market, and use cases.

2️⃣ Test Setup:

• Install sensors and configure equipment (shock systems, vibration shakers, environmental chambers).

3️⃣ Simulate Environmental Conditions:

• Subject the product to specific test cycles and stress levels (temperature, vibration profiles, shock pulses, drop heights).

4️⃣ Collect Data:

• Monitor product behavior in real time using sensors and data acquisition systems.

5️⃣ Analyze Results:

• Assess whether the product meets pass/fail criteria for performance, integrity, and safety.

Example: IEC 60068-2-27 Shock Testing

A typical test might involve securing a product on a TMC shock testing system and applying controlled shock pulses up to several thousand g’s to simulate sudden handling impacts or operational shocks—validating its mechanical resilience.

Industries that Rely on IEC Environmental Testing

• Aerospace: Validate airframe components, avionics, and flight-critical systems under extreme vibration and temperature cycles.

• Automotive: Ensure durability of batteries, sensors, and infotainment systems under thermal and vibration stresses.

• Consumer Electronics: Test smartphones, tablets, and appliances for drop, shock, vibration, and ingress protection.

• Defense: Certify mission-critical systems for reliability in harsh field environments.

• Industrial Equipment: Validate machinery, sensors, and controllers for vibration and climate extremes in field deployments.

TMC Solutions: Your Partner in IEC-Compliant Testing

At TMC Solutions, we specialize in advanced reliability testing systems built to meet IEC standards:

✅ Hydraulic Shaker Systems — For IEC 60068-2-6 vibration and combined environments

✅ Shock Testing Systems — For IEC 60068-2-27 mechanical shock, IEC 60068-2-31 drop testing

✅ Centrifugal Constant Acceleration Test Systems — For sustained acceleration tests

✅ Motion Systems and Rate Tables — For precise movement simulations

✅ Small Shakers — For component-level vibration testing

Our systems help customers achieve faster time to market, reduced failure rates, and compliance with global standards.

➡️ Explore TMC’s full range of products

Building Reliability with IEC Environmental Testing

In a world where product performance is tied to brand reputation, IEC environmental testing is your frontline defense against failure. Whether for aviation, automotive, defense, or consumer markets—rigorous testing builds trust.

TMC Solutions proudly supports global manufacturers with advanced testing equipment engineered to meet the latest IEC requirements. If you’re ready to elevate your product testing strategy, let’s talk.

📩 Contact TMC today for expert guidance on IEC environmental testing.