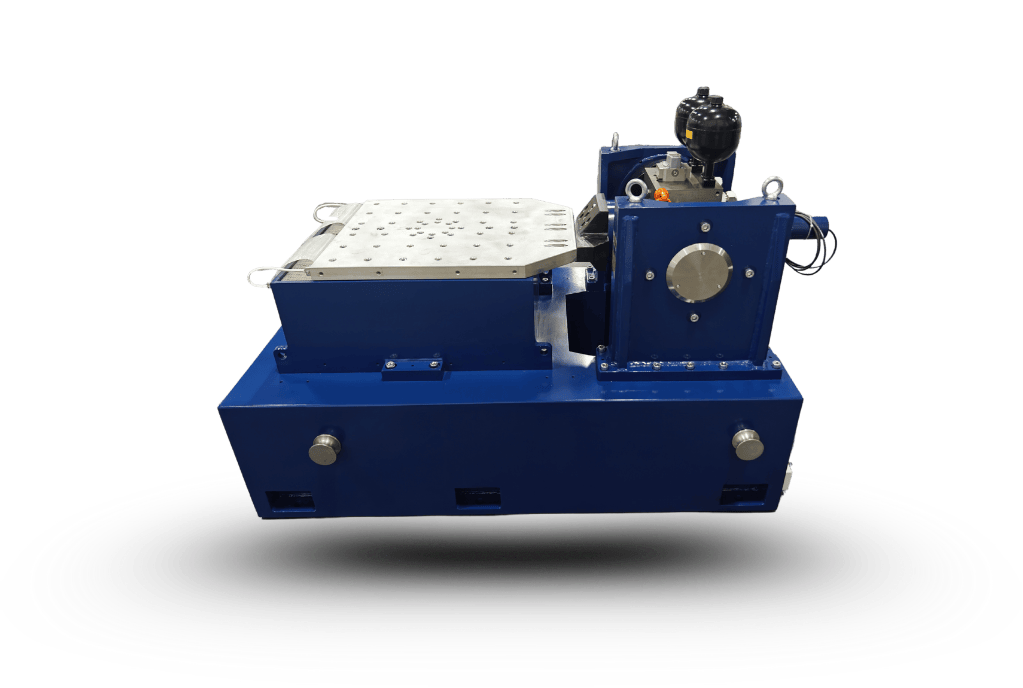

HS Series Hydraulic Shaker for Rigorous Testing

HS hydraulic shaker system is designed for high-precision testing under various conditions, offering a high degree of automation and reliability. It supports vertical and horizontal vibration modes and can simulate sine, random, and road spectrum waveforms. This system is widely used to evaluate a product’s structural durability and adaptability in simulated transportation or operational environments. Easy to operate and PC-controlled, the HS series enables accurate testing and data analysis to help optimize product performance. Its ability to replicate real-world vibration conditions plays a key role in improving product reliability and ensuring consistent quality in practical applications.

HYDRAULIC VIBRATION SHAKER FEATURES

Large test table and high force output

The HS series features a robust, large-size table engineered for high payload capacity and long stroke applications, ideal for seismic simulation of large and heavy specimens.

Precision guide rail system

Utilizes low-friction guide rail sliding with excellent linearity, ensuring stable motion and easy maintenance during long-term operation.

Advanced hydraulic system

Equipped with a high-performance servo valve and hydraulic cylinder, the system delivers reliable force output and accurate vibration control for demanding test scenarios.

Efficient damping system

Integrated damping devices reduce shock transmission to the lab floor, minimizing the need for special foundations and simplifying installation.

Flexible vibration simulation

Capable of generating sine, random, and road spectrum vibrations, the system offers high adaptability for various industry standards and test protocols.

PC-based control and measurement

The control system includes a vibration controller, sensors, and servo control cabinet, all managed via a user-friendly PC interface for automated and precise testing workflows.

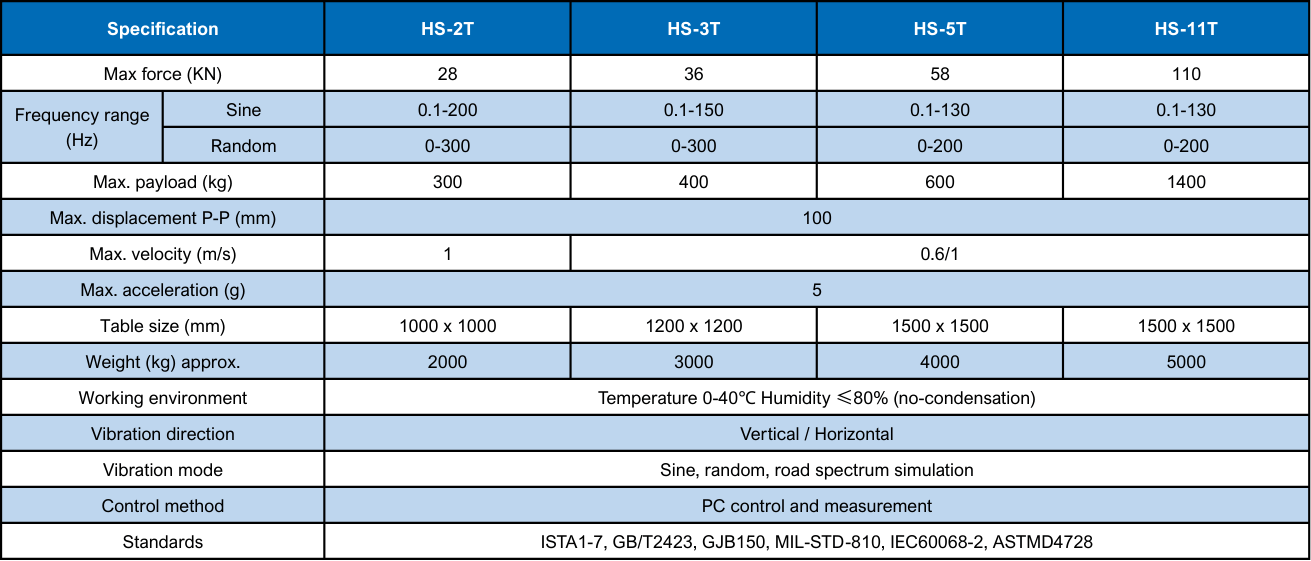

DOWNLOAD DATASHEET