How ASTM Material Testing Drives Product Quality

Discover the basics of ASTM material testing and how it impacts the quality of industrial products.

What is ASTM Material Testing?

When people search for “ASTM material testing,” they are usually asking:

What does ASTM stand for?

What is material testing?

Why do manufacturers need it?

How does it improve product quality?

Which industries rely on ASTM standards?

Let’s break it down:

ASTM stands for the American Society for Testing and Materials (now called ASTM International).

Founded in 1898, ASTM develops and publishes voluntary consensus standards — recognized worldwide — that ensure product quality, safety, and reliability.

Material testing refers to standardized procedures that evaluate a material’s physical, chemical, or mechanical properties — such as strength, hardness, ductility, fatigue, corrosion resistance, and more.

ASTM material testing combines both:

➡️ Using ASTM-defined methods to test and certify materials for industrial use.

Why is ASTM Material Testing Important?

1️⃣ Ensures Product Quality & Performance

Manufacturers want to be sure the materials they use meet strict criteria — otherwise, final products may fail under real-world conditions.

ASTM testing verifies that materials are:

✅ Fit for purpose

✅ Consistent from batch to batch

✅ Able to meet customer expectations

✅ Compliant with international markets

2️⃣ Promotes Safety

Especially in critical industries — aerospace, automotive, energy, defense — unsafe materials can have catastrophic consequences.

ASTM material testing reduces the risk of:

⚠️ Structural failures

⚠️ Premature wear and tear

⚠️ Accidents and recalls

⚠️ Liability for manufacturers

3️⃣ Supports Global Trade & Market Access

ASTM standards are widely recognized — more than 12,000+ active standards — covering materials like metals, plastics, rubber, textiles, composites, coatings, and more.

By complying with ASTM standards, manufacturers:

✅ Demonstrate quality to customers

✅ Streamline export and import approvals

✅ Open new markets globally

✅ Build stronger customer trust

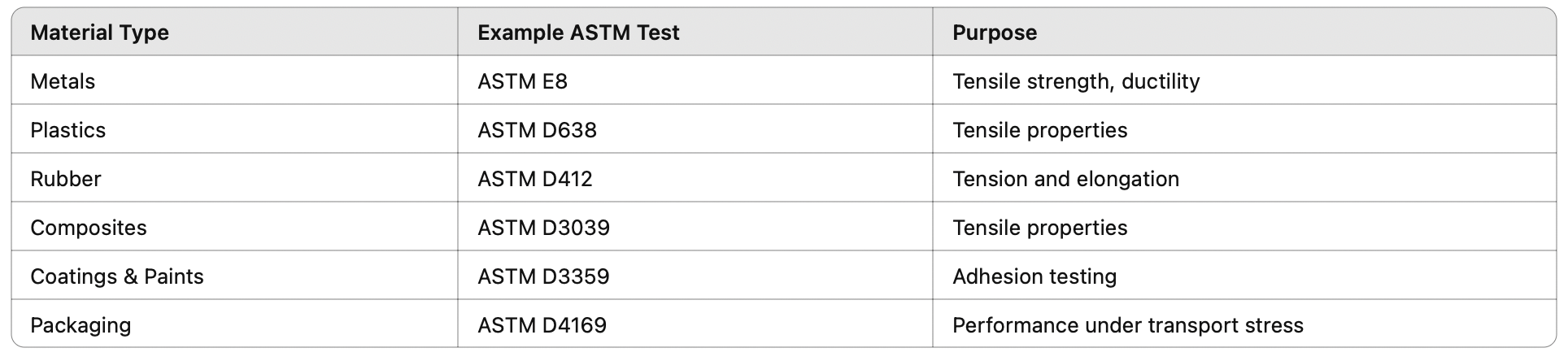

What Are Some Common ASTM Material Tests?

How Does TMC Solutions Support ASTM Material Testing?

At TMC Solutions, we specialize in reliability testing equipment that helps manufacturers comply with ASTM standards and beyond.

Our systems include:

✅ Hydraulic shaker systems — simulate vibration fatigue & endurance (ASTM D999)

✅ Shock test systems — evaluate impact resistance (ASTM D4169)

✅ Drop test systems — replicate handling & transportation stresses (ASTM D5276)

✅ Incline impact systems — test for load shifts during shipping

✅ Centrifugal constant acceleration test systems — assess product durability

✅ Motion simulators & rate tables — validate material behavior under motion stresses

We help clients from automotive, aerospace, defense, packaging, and energy sectors achieve ASTM compliance through:

✅ Precision-built equipment

✅ Customized solutions for your product needs

✅ Integrated systems with climatic chambers

✅ Technical support & consultation

Why ASTM Material Testing Matters

ASTM material testing isn’t just about checking boxes — it’s about:

Ensuring product reliability

Protecting user safety

Gaining competitive advantage

Opening new markets

Driving continuous improvement in quality

TMC Solutions is your trusted partner in this process — providing advanced testing equipment that helps you meet ASTM standards and elevate your brand reputation.

Ready to learn more?

➡️ Contact our team — let’s help you design the ideal testing setup for your materials!