Advancing Defense Testing with TMC Shock Systems

In defense applications, the stakes are incredibly high. Every component, system, or piece of equipment must perform flawlessly under extreme conditions. From shockwaves generated by rocket launches to the sudden impacts caused by artillery firing, the environments faced by defense products demand rigorous testing.

How Environmental Factors Impact Shock Test Results

In the world of product reliability, shock testing is an essential process to evaluate the structural integrity and durability of components under real-world conditions. However, to truly replicate real-world scenarios, manufacturers must account for various environmental factors—such as temperature, humidity, and pressure—that can significantly influence shock test results.

Boosting Precision with Motion Simulators & Rate Tables

In the fast-evolving industries of aerospace, automotive, and defense, ensuring product precision and reliability is a top priority. Motion simulators and rate tables have become indispensable tools in achieving this goal. By simulating real-world movements and testing rotational accuracy, manufacturers can refine their components to meet stringent quality standards and perform flawlessly in demanding environments.

Mastering Incline Impact Testing for Product Durability

In industries where products undergo frequent handling, transportation, and storage, ensuring durability and resilience is crucial. The incline impact testing system is an essential tool for manufacturers to assess how well their packaging and products can withstand impacts that may occur during their lifecycle.

Hydraulic vs. Electromagnetic Vibration Shakers

In the realm of vibration testing, choosing the right type of vibration shaker can be crucial for achieving accurate and reliable results. Two primary types of vibration shakers dominate the industry: hydraulic vibration shakers and electromagnetic (or electrodynamic) vibration shakers.

Optimizing Testing with Constant Acceleration Systems

In industries such as aerospace, automotive, electronics, and defense, ensuring product durability under various operational conditions is critical. One of the most important testing methods for validating product reliability and structural integrity is the centrifugal constant acceleration test.

Enhancing Packaging Safety with Drop Test Machines

In today's fast-paced global economy, products are often shipped across long distances and through various modes of transport. As a result, packaging plays a critical role in protecting products from damage during transit. However, even the most well-designed packaging can be subjected to sudden drops, impacts, and collisions, which could potentially compromise the integrity of the product inside.

Simulating Real-World Shocks for Product Reliability

In today’s competitive market, ensuring product reliability is critical for maintaining customer satisfaction and avoiding costly recalls. Whether you are in the aerospace, automotive, consumer electronics, or defense industry, products are often subjected to real-world shocks during shipping, installation, and operation.

Choosing the Right Shock Test System for Your Product

As industries like automotive, aerospace, consumer electronics, and defense continue to advance, the need for reliable products is more critical than ever. One of the most effective ways to ensure product durability and longevity is by conducting shock testing.

Reliability Testing in Aerospace & Automotive

In high-stakes industries like aerospace and automotive, ensuring the reliability of components and systems is not just essential—it’s critical for safety, performance, and longevity. Both sectors operate under conditions that challenge every part of the vehicle or aircraft, from the engines and electronics to materials and structures.

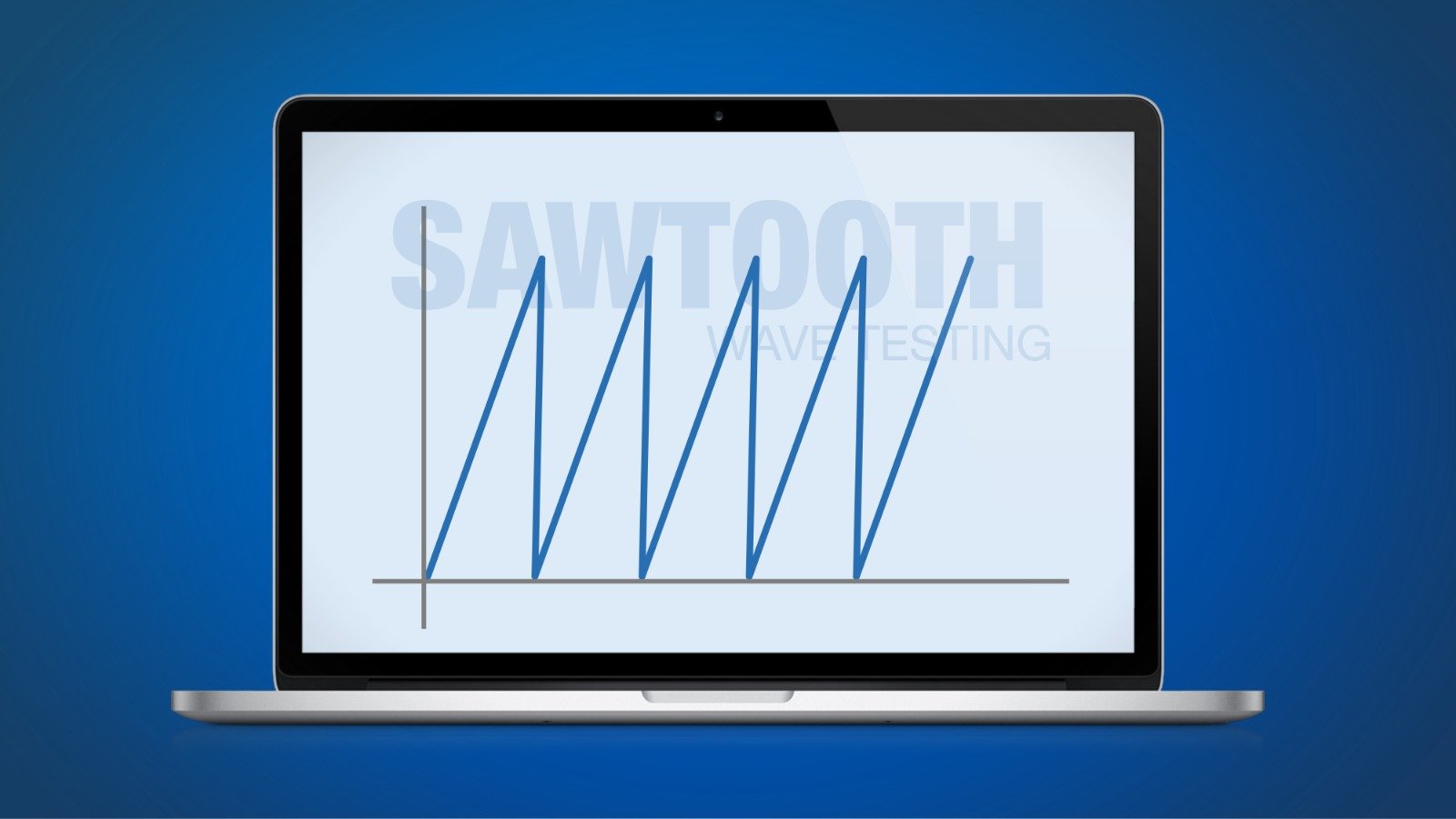

Sawtooth Wave Testing for Product Durability

In the field of mechanical testing, ensuring that a product can withstand the harsh conditions it may face during its lifecycle is crucial. One critical test for this is shock testing, which simulates the physical shocks that a product might experience during transportation, handling, or use.

VT Series: Compact Shaker for Precision Vibration Testing

TMC Solutions' VT Series Small Vibration Test System is engineered specifically to meet the needs of modern manufacturers seeking a compact, efficient, and reliable solution for vibration testing of smaller components and products.

Enhancing Safety with Hydraulic Vertical Shock Test Systems

In industries such as electronics, automotive, and aerospace, ensuring product durability during manufacturing, transportation, and real-world use is paramount. A critical part of this process is shock testing, where products are subjected to controlled impacts to assess their structural integrity and performance.

Ensuring Product Reliability with Shock and SRS Tests

In the dynamic and ever-evolving world of electronic and mechanical products, ensuring reliability under extreme conditions is crucial. One of the most effective ways to achieve this is through shock testing and analyzing the Shock Response Spectrum (SRS).

Guide to Selecting Your Ideal Centrifuge System

When it comes to ensuring the reliability and performance of electrical and electronic products, constant acceleration testing is a critical process. According to national standards, the purpose of constant acceleration tests is to determine whether the structural adaptability and performance of components, equipment, and other electronic products can withstand forces generated by a steady-state acceleration environment.

Mechanical Shock Testing for Electronics Reliability

In today’s fast-paced technological world, electronic products are exposed to various mechanical shocks throughout their lifecycle—from production and handling to transportation and everyday use. Mechanical shock testing plays a critical role in verifying a product’s ability to withstand these shocks, ensuring its reliability and longevity.

Inside TMC’s Hydraulic Shaker: Features & Benefits

TMC Solutions has established itself as a leader in the field of reliability testing equipment. One of the standout products in their lineup is the hydraulic shaker, designed to perform a wide range of environmental vibration tests, including sine, random, shock, resonance search, and dwell vibration tests.

Exploring the Versatile Box-Type Centrifuge Tester

The box type centrifuge is a standout in laboratory equipment, known for its versatility and capability, making it essential for various scientific and industrial applications.

Ensuring Reliability and Longevity of EV Batteries

The rapid adoption of electric vehicles (EVs) is a critical component of the global transition to sustainable transportation. As EV technology continues to evolve, the reliability and longevity of EV batteries remain paramount.

The Importance of Testing Electronic Parts of Aerospace Devices with Constant Acceleration Test Machines

In the high-stakes world of aerospace, the reliability and integrity of electronic components are non-negotiable. Every part, no matter how small, must perform flawlessly under extreme conditions to ensure the safety and success of missions.