SRS vs. Classical Shock: A Paradigm Shift in Product Testing

Introduction: Rethinking Shock Testing

In product qualification and reliability engineering, shock testing plays a vital role in ensuring that devices survive sudden mechanical events—drops, impacts, and transportation jolts. Traditionally, this has been done using Classical Shock methods that specify a predefined pulse in the time domain.

But modern products are more complex than ever. They contain components with different natural frequencies, sensitivities, and failure modes. For such systems, Shock Response Spectrum (SRS) testing offers a more intelligent and predictive approach—one that focuses not just on the input force, but on how that force affects the entire system.

This article explores why the shift from Classical Shock to SRS represents a major paradigm change in mechanical testing—and how engineers can harness it to design more robust products.

Classical Shock: Simple and Familiar, But Limited

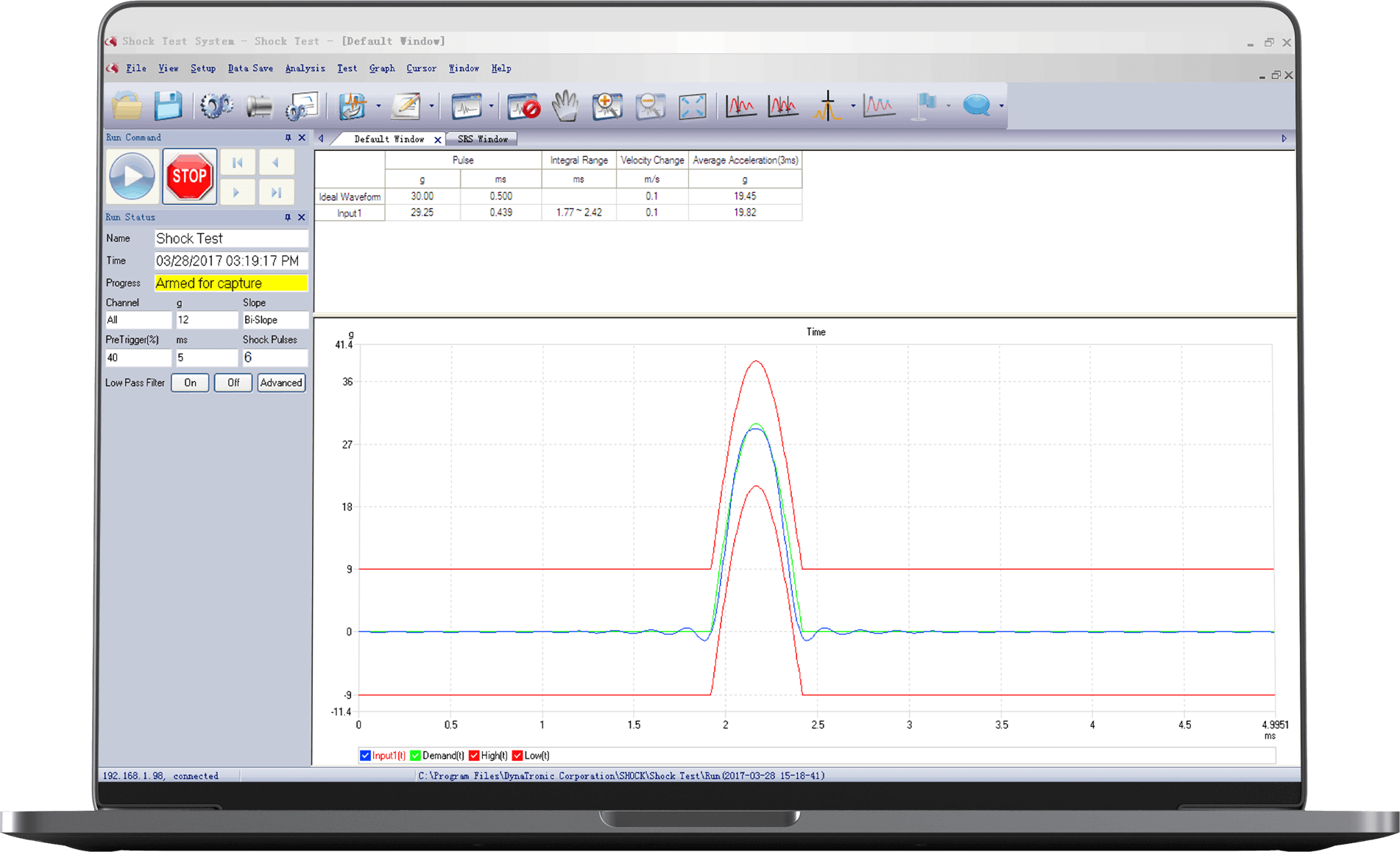

Classical shock testing defines a mechanical shock by its waveform in the time domain, typically characterized by:

Pulse shape (e.g., half-sine, terminal sawtooth, trapezoidal)

Peak acceleration (measured in Gs)

Pulse duration (in milliseconds)

Example:

A “50G, 11ms half-sine pulse” means a single arc-shaped acceleration event peaking at 50G and lasting 11 milliseconds.

This approach describes the input force applied at the base of a product. It's useful for basic impact simulation, but has serious limitations:

It does not account for internal resonances.

It ignores how different components will respond to the shock.

It assumes the waveform alone is enough to predict damage.

In short, Classical Shock tells you what happened—SRS tells you what it did to your system.

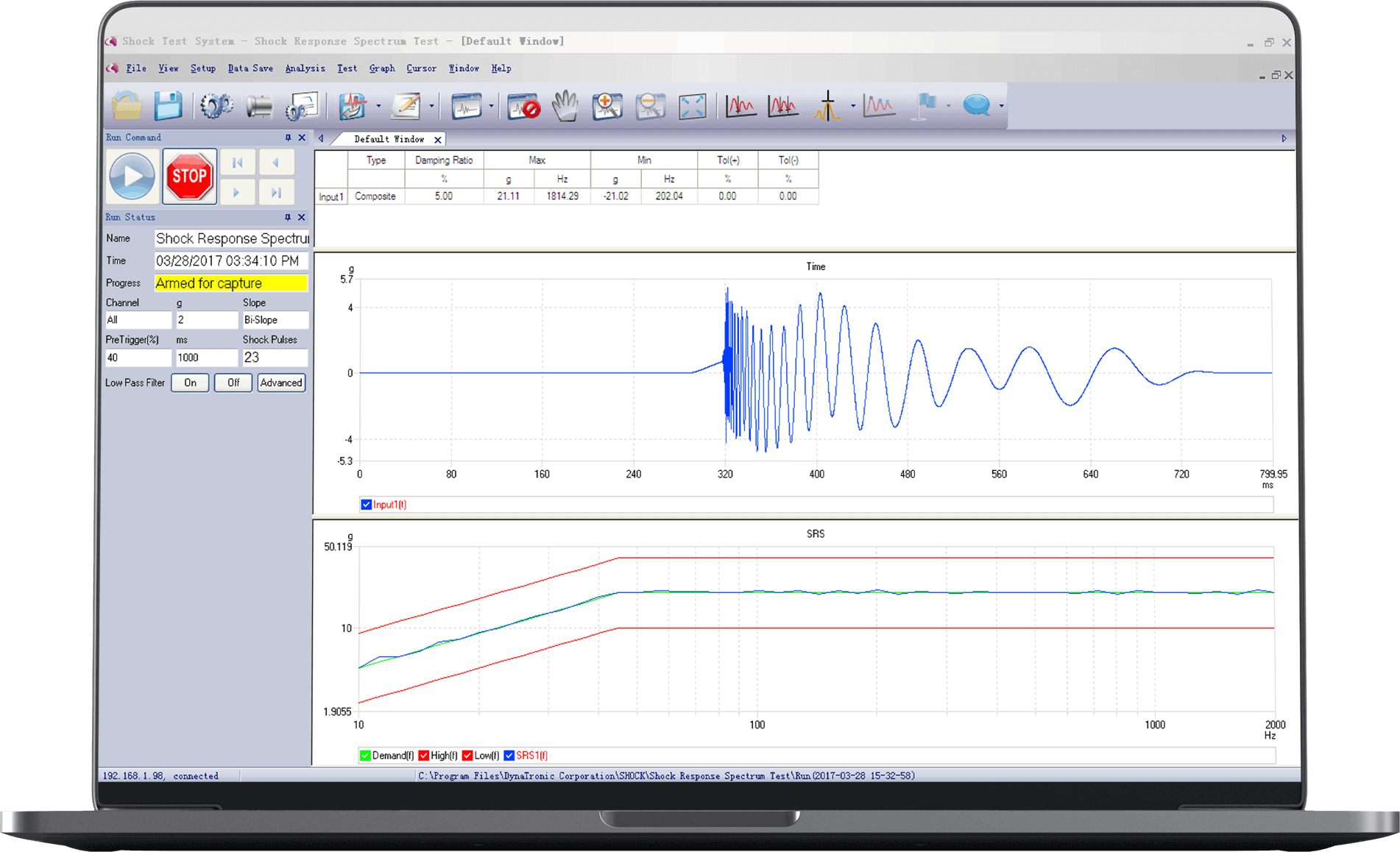

Shock Response Spectrum (SRS): A More Advanced Lens

The Shock Response Spectrum defines a shock by its effect rather than its shape. It’s a plot in the frequency domain that answers one essential question:

“If my component had a natural frequency of X Hz, what is the maximum acceleration it would experience during this shock?”

This makes SRS particularly valuable for modern devices with multiple fragile subsystems—like sensors, PCB-mounted chips, and connectors—each with its own resonant frequency.

Example: "A shock that produces a response of 100G at 100 Hz, 75G at 500 Hz, and 50G at 2000 Hz."

Visualizing the SRS:

Imagine a mountain range on a graph:

X-axis: Frequency (Hz)

Y-axis: Peak Response Acceleration (G)

Each “peak” represents how much a given frequency band was excited. This gives engineers a clear and quantitative view of potential damage, even when two input shocks may look similar on paper.

Why the Difference Matters: A Real-World Case

Scenario:

A team is testing a new data logger for logistics and transport. The requirement is to pass a "50G, 11ms" shock test.

Two labs run the test:

Lab A uses a Half-Sine waveform. The product passes.

Lab B uses a Terminal Sawtooth waveform. The product fails—one memory chip detaches from its socket.

Why?

While both shocks had identical peak Gs and durations, their shapes were drastically different:

The Sawtooth pulse has a sharper acceleration rise, resulting in higher frequency energy.

The SRS showed that the Sawtooth generated over 120G of acceleration at 800 Hz—the resonant frequency of the failed chip.

The Half-Sine was gentle in that frequency range, so the part survived.

Key Insight:

The test condition looked the same—but the internal stress on the product was completely different. Only SRS analysis revealed the truth.

Why Engineers Are Shifting Toward SRS

In today’s product development cycle, there’s no room for trial-and-error. Engineers need predictive tools that mirror real-world damage potential, especially when:

Products contain high-density PCBs or MEMS components.

There are multiple shock directions or combined environments.

Regulatory or customer standards require realistic failure mode analysis.

SRS offers several benefits:

✅ Component-level insight

✅ Broad frequency coverage

✅ Alignment with field data

✅ Improved reliability predictions

SRS Is the Future of Shock Testing

The move from Classical Shock to SRS represents more than just a technical upgrade—it’s a philosophical shift in how engineers define, simulate, and validate product durability.

By focusing not just on the shock itself, but on how it affects your system, SRS allows for a smarter, more resilient approach to product development.

At TMC Solutions, we support this shift by offering equipment, software, and engineering services that help our clients implement SRS-based testing, align with modern standards, and build products that last.

Want to Learn More?

📞 Contact our team to learn how we can help you integrate SRS testing into your shock qualification strategy.

📚 Need help converting classical specs into SRS equivalents? Let’s talk.