Benefits of Using Hydraulic Shaker Systems

Benefits of Using Hydraulic Shaker Systems for Vibration Testing

Learn how hydraulic shaker systems offer unmatched performance for high-load, low-frequency and large displacement vibration testing across industries.

In industries like automotive, aerospace, defense, transportation, and heavy equipment manufacturing, vibration testing is a critical step to ensure product reliability, safety, and compliance with international standards. Among the available technologies, hydraulic shaker systems stand out as a powerful solution for large payloads and low-frequency vibration testing—capabilities that traditional electrodynamic (ED) shakers often struggle to match.

At TMC Solutions, we specialize in high-performance hydraulic shaker systems designed to meet the most demanding test conditions. Let’s explore the key advantages, applications, and how our innovative technology is reshaping the future of vibration testing equipment.

What is a Hydraulic Shaker System?

A hydraulic shaker is a test system that uses hydraulic actuators to generate vibration forces. Unlike ED shakers, which use electromagnetic coils, hydraulic shakers rely on fluid pressure—making them ideal for delivering high-force, low-frequency vibrations and accommodating large or heavy test articles.

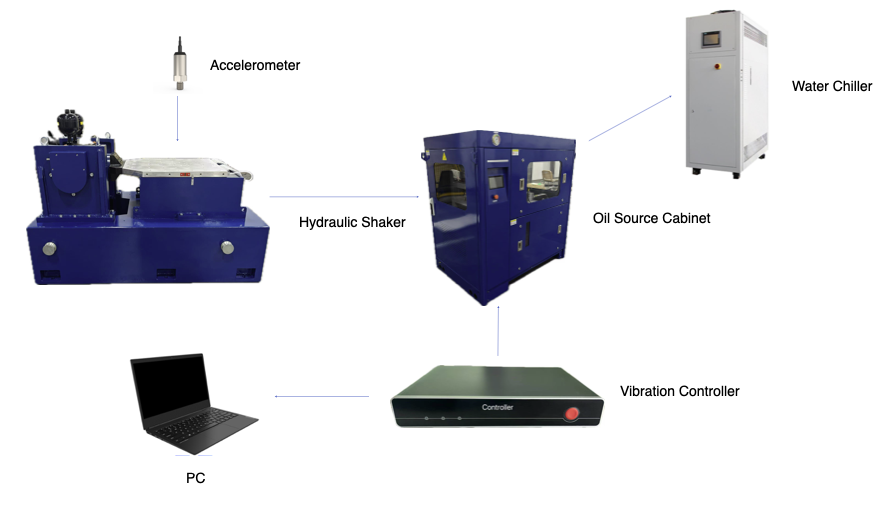

Standard Hydraulic Shaker Components

Vibration Table

Actuator/Piston Assembly

Hydraulic Power Supply

Hydraulic Manifold

Servo Valve

Servo Controller

Vibration Controller

Which industry standards does the hydraulic shaker system comply with?

TMC Solutions’ Hydraulic Shaker Systems are designed to comply with a range of international and industry-specific testing and safety standards, ensuring they meet the requirements of reliability, performance, and regulatory compliance. The most relevant standards include:

IEC 60068 Series

Environmental testing – Part 2-6 (IEC 60068-2-6): Tests for vibration (sinusoidal)

Part 2-27 (IEC 60068-2-27): Shock testing

Part 2-64 (IEC 60068-2-64): Random vibration testing

Application: Used widely in automotive, electronics, defense, and aerospace sectors for vibration and mechanical shock qualification.

MIL-STD-810

U.S. Military Standard for Environmental Engineering Considerations and Laboratory Tests

Covers vibration, shock, and acceleration requirements for military-grade equipment.

Application: Defense and aerospace industries.

ASTM Standards

Such as ASTM D999 (Standard Test Methods for Vibration Testing of Shipping Containers) and ASTM D4169 (Performance Testing of Shipping Containers).

Application: Transportation simulation testing, especially for packaging.

ISTA Testing Standards

ISTA 1 Series, ISTA 2A, 3E, etc., for vibration testing under packaging and transportation conditions.

Application: Logistics and packaging industries.

If you’re targeting specific standards for your project (e.g., IEC 60068-2-64 for random vibration or MIL-STD-810G for rugged military environments), TMC can customize the system to support your certification requirements.

Advantages of Hydraulic Shaker Systems

TMC’s standard Hydraulic Shaker force range from 28kN to 540kN and we can customize greater force as per request. The frequency range is from 0.1 Hz to 300 Hz (random) and can be customized. There are various multi-axial and multi-DOF design.

Unmatched Force and Displacement

TMC’s HS-20T hydraulic shaker, for example, delivers a sine force of ≥200kN and a maximum displacement of ±165mm, making it ideal for simulating real-world conditions for payloads up to 5000kg. This level of power is particularly critical when testing heavy vehicle components, structural assemblies, or large packaging systems.

Better Simulation of Real-World Environments

Hydraulic systems excel in replicating complex vibration profiles such as:

• Random vibration

• Sine sweeps

• Seismic waves

• Long-wave low-frequency signals

This allows for more accurate simulation of operational environments including transportation bumps, road-induced loads, and even battlefield shocks.

Wide Frequency Range

Hydraulic systems like TMC’s can operate in a frequency range from 1Hz to 200Hz, covering most low-frequency environmental requirements that ED shakers typically cannot.

Greater Payload Flexibility

Where electrodynamic systems hit limitations in mass and displacement, hydraulic shakers shine. TMC’s MET6-10T 6-DOF system, for instance, accommodates test specimens up to 10 tons, offering six degrees of freedom (DOF) including translational and rotational axes.

Hydraulic Shakers vs. Electrodynamic Shakers

Applications Across Industries

Automotive Industry

Hydraulic shaker systems play a vital role in the automotive sector, where vibration testing is crucial to ensure the safety, reliability, and longevity of vehicles. These systems simulate real-world road conditions to assess the performance of engine mounts, exhaust systems, suspension assemblies, dashboards, and vehicle electronics. For instance, simulating the long-term vibrations experienced by suspension systems on rough terrain helps manufacturers identify potential fatigue failures before market release. Hydraulic shakers also support vehicle transport simulation testing, helping meet regulatory standards and reducing warranty claims.

Aerospace Industry

In the aerospace field, components must endure extreme environments, including intense vibration during launch, flight, and landing. Hydraulic vibration shakers are used to test structural airframe elements, avionics enclosures, satellite subsystems, and engine assemblies. By reproducing launch-induced vibration profiles, these systems help aerospace engineers ensure that sensitive electronics and mechanical parts remain operational under harsh dynamic conditions. This level of reliability is critical for safety and compliance with aerospace standards such as DO-160 and MIL-STD-810.

Defense and Military Sector

Defense applications demand robust and fail-proof equipment that can withstand battlefield vibrations, transport shocks, and explosive impacts. TMC hydraulic shakers are employed to test mission-critical military electronics, missile guidance systems, communication gear, ruggedized computing devices, and more. The systems simulate operational environments—including cross-country transport and combat zone vibrations—to confirm durability under the toughest scenarios. Many of these tests align with military standards like MIL-STD-202 and MIL-STD-810G/H.

Transportation and Packaging

Hydraulic vibration shakers also serve in the packaging and logistics industry, where ensuring product integrity throughout the supply chain is paramount. Testing according to international standards such as IEC 60068-2-64 and ISTA 3E allows manufacturers to simulate the vibrations that packages endure during air, sea, and ground transport. These tests help validate packaging designs for electronic devices, medical equipment, consumer goods, and automotive parts—minimizing the risk of product damage and reducing return rates.

Why Choose TMC Solutions?

Robust engineering: All systems designed for minimal waveform distortion and maximum safety.

Precise control: Digital servo controllers with real-time feedback and automatic safety mechanisms.

Customizable setups: Table sizes, control interfaces, and modular oil systems tailored to your testing needs.

Proven performance: From our HS-2T to 6-DOF dynamic hydraulic shakers, we deliver cutting-edge reliability testing equipment backed by years of R&D.

Invest in What Moves the Industry Forward

Hydraulic shakers are not just powerful—they’re essential. When your test requirements exceed what traditional vibration equipment can deliver, a hydraulic shaker system from TMC Solutions ensures you don’t compromise on accuracy, safety, or performance.

Whether you’re looking to simulate harsh environments or conduct precision durability tests for large components, TMC’s hydraulic vibration testing systems are built to move your products—and your business—forward.

👉 Ready to elevate your testing capabilities?

Contact us today.