Incline Impact Testing: Key Facts for Pre-Shipment Success

In the world of global logistics, packaging doesn’t just protect products — it protects brands. One of the most critical yet under-discussed methods in package validation is the Incline Impact Test. This testing method, commonly required under ISTA 3E standards, simulates what happens when a package in transit slams into another during handling, transport, or storage.

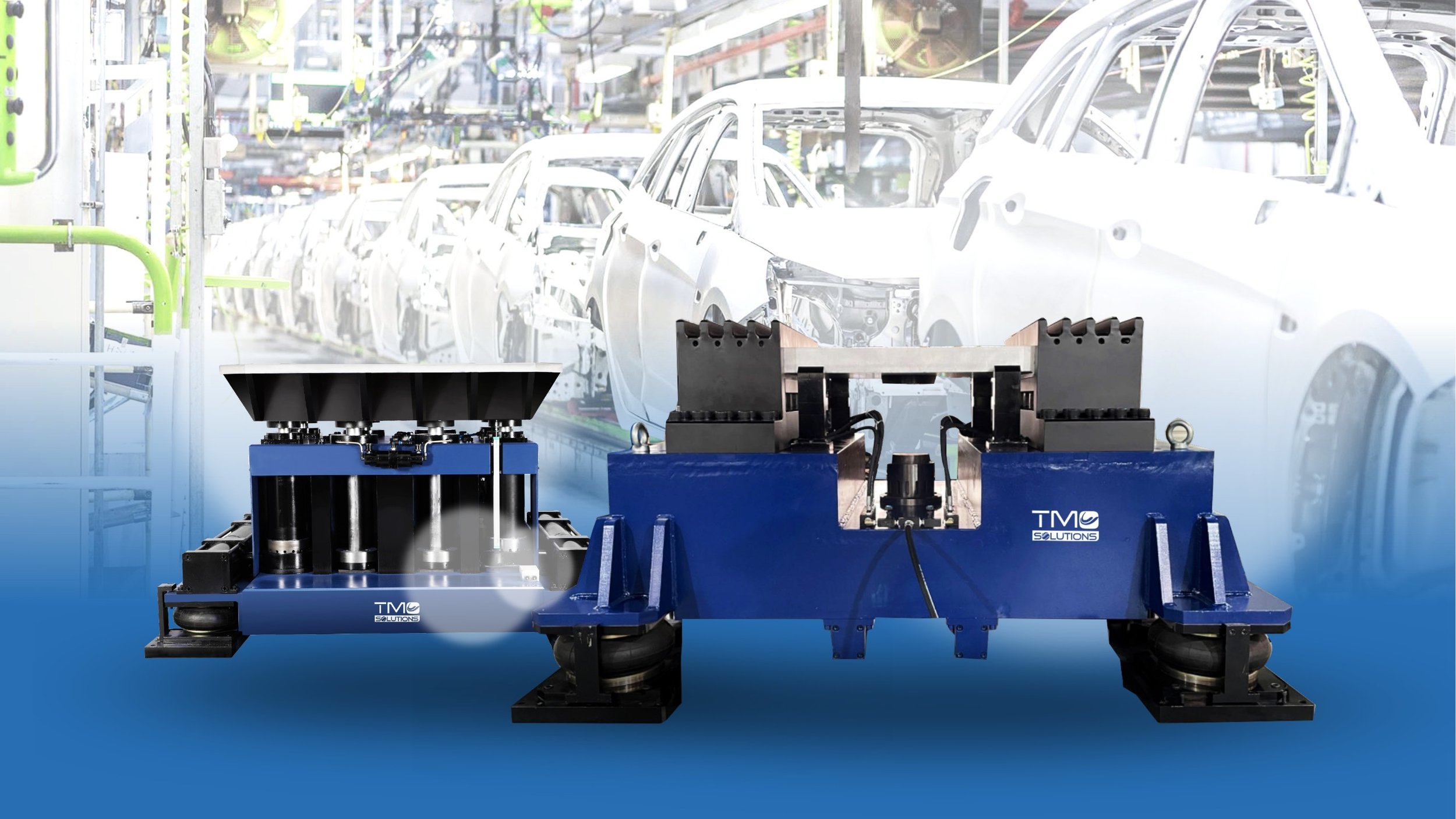

How Environmental Factors Impact Shock Test Results

In the world of product reliability, shock testing is an essential process to evaluate the structural integrity and durability of components under real-world conditions. However, to truly replicate real-world scenarios, manufacturers must account for various environmental factors—such as temperature, humidity, and pressure—that can significantly influence shock test results.

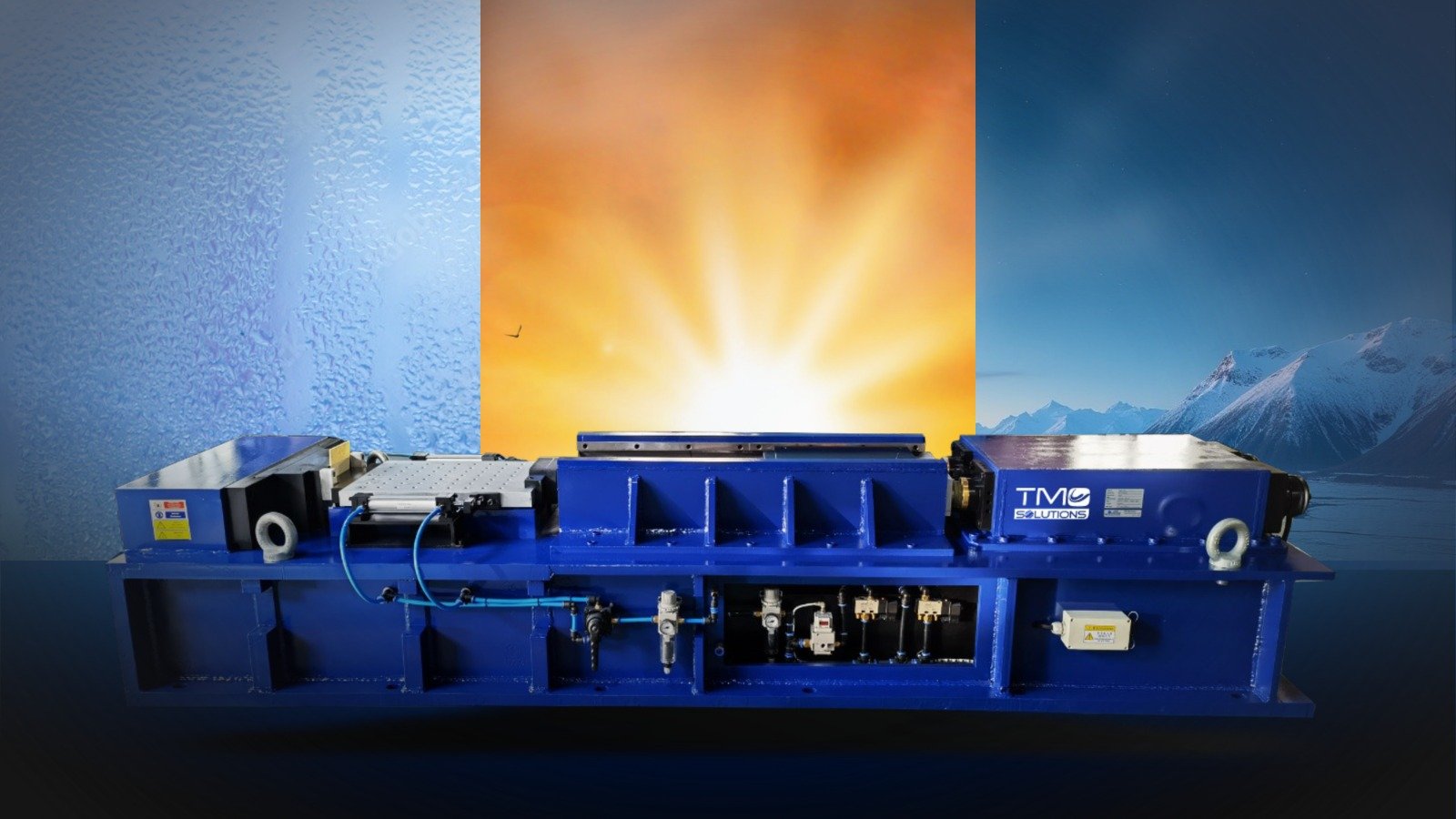

Mastering Incline Impact Testing for Product Durability

In industries where products undergo frequent handling, transportation, and storage, ensuring durability and resilience is crucial. The incline impact testing system is an essential tool for manufacturers to assess how well their packaging and products can withstand impacts that may occur during their lifecycle.

The Benefits of Partnering with a Reliable Testing Solutions Provider

In today’s highly competitive and technologically advanced market, the need for reliable testing solutions has never been more critical. Whether you are in aerospace, automotive, electronics, or any other industry, ensuring the durability and reliability of your products is paramount. Partnering with a reliable testing solutions provider can make all the difference in achieving these goals.