Mastering ISTA Drop Testing for Packaging

Complete Guide to ISTA Drop Test Systems for Packaging Reliability

Why Drop Testing Matters in Product Durability

In today’s global shipping and logistics landscape, products endure rough handling, long-haul transportation, and varied storage conditions. Whether it’s consumer electronics, heavy-duty machinery, or medical devices—packaging and product integrity must withstand real-world forces.

That’s where drop test systems come into play.

Drop testing simulates accidental falls, impacts during transit, and everyday drops that could damage a product or its packaging. It’s not just about preventing cracks—it’s about ensuring reliability, reducing warranty claims, and maintaining customer satisfaction.

At TMC Solutions, we specialize in delivering precision drop test systems that comply with ISTA standards, offering customizable solutions for diverse industries and product specifications.

What is ISTA Drop Testing?

ISTA (International Safe Transit Association) sets standardized test procedures to simulate the physical hazards products face in distribution. Drop testing, a vital element of these standards, helps determine whether packaging can adequately protect the product during transit.

Below is the detailed information of ISTA Series Drop Testing Standards

ISTA 1 Series: Non-simulation integrity drop testing standard for basic screening during early design

ISTA 2 Series: Enhanced non-simulation integrity drop testing standard

ISTA 3 Series: General simulation performance testing

ISTA 6 Series: Member-specific protocols (e.g., Amazon, FedEx, Sam’s Club) simulating real-world supply chain conditions

TMC Solutions’ ISTA-Compliant Drop Test Systems

Based on the above standards, TMC has small drop test machine with drop range 300-1500mm and 300-2000mm, zero distance drop test machine and double lift zero distance drop test machine.

Small Drop Test System

Zero Distance Drop Test System

Double Lift Zero Distance Drop Test System

Application Examples

PROJECT ONE

Drop height range (mm): 300-1500

Max. Specimen weight (kg): 85

Max. Specimen dimensions (mm): 800x800x800

Drop mode: Freefall

Customer wants to do surface, edge and corner drop

Based on the requirement, we provided DS150 and below photos show how to do surface, edge and corner dop.

TMC Drop Test System DS150 - Edge Drop

TMC Drop Test System DS150 - Corner Drop

TMC Drop Test System DS150-Surface Drop

PROJECT TWO

Specimen weight: 500kg

Specimen dimensions: 24" L x 24" W x 72" H (610x610x1829mm), 36" L x 28" W x 48" H (915x711x1219mm), 50" L x 28" W x 86" H (1270x711x2184mm)

Drop height: 0-1550mm

Special requirements 1: customer requires two double lift zero distance drop testers to work simultaneously

Special requirements 2: the single drop tester can work independently if there is small package

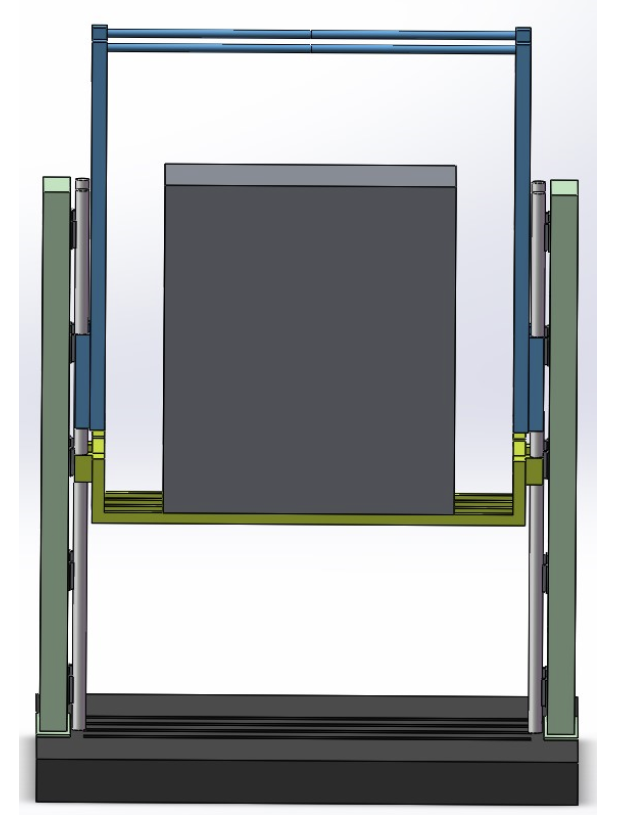

Based on the requirement, we provided customized system NDS500C. NDS500C is a customized system composed of two single double lift zero distance drop tester. The two drop testers can work simultaneously and each of them can work separately.

Below are the design schemes of this customized system.

Specimen dimensions: 24" L x 24" W x 72" H (610x610x1829mm)

Specimen dimensions: 36" L x 28" W x 48" H (915x711x1219mm)

Specimen dimensions: 50" L x 28" W x 86" H (1270x711x2184mm)

TMC Drop Test - corner drop test

TMC Drop Test - corner drop test

TMC Drop Test - edge drop test

TMC Drop Test - edge drop test

TMC Drop Test - surface drop test

TMC Drop Test - surface drop test

Why Choose TMC Solutions for ISTA Testing?

✅ Custom Engineering – From small units to massive packaging systems

✅ Accuracy & Repeatability – High-precision equipment with intuitive control

✅ Versatile Drop Modes – Surface, edge, and corner testing covered

✅ Test Various Package Sizes – Easily accommodate small to extra-large products

✅ Meets ISTA Standards – Ensures your product packaging meets global compliance

ISTA drop testing is a cornerstone of reliable packaging design. TMC Solutions offers cutting-edge drop test systems tailored to meet your exact testing needs and ensure your packaging is ISTA-certified and logistics-ready. From initial R&D to full-scale quality control, our machines are built to deliver confidence at every drop.

🔗 Explore our Drop Test Systems

📩 Contact us to find the right equipment for your packaging requirements.