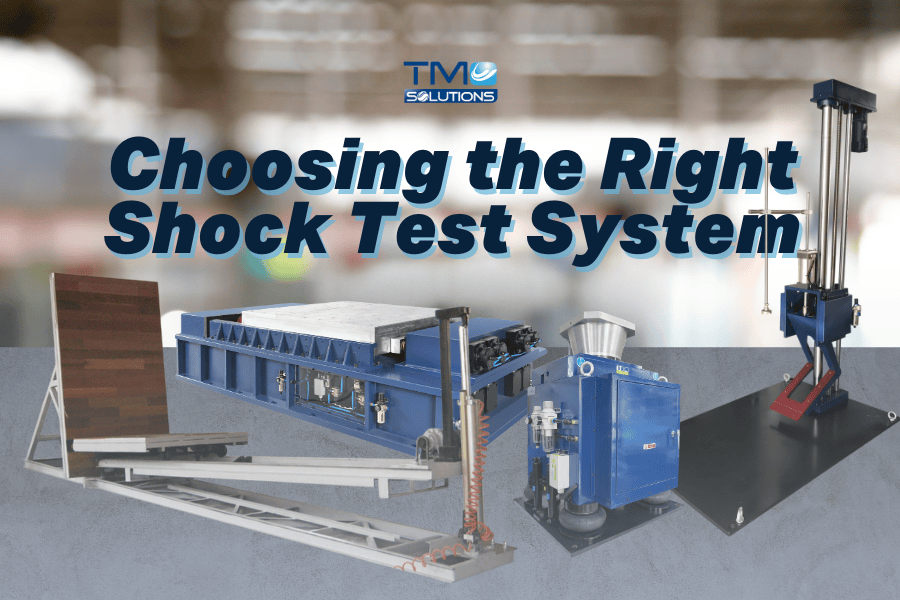

How to Choose the Right Shock Test System for Your Industry

In industries where product performance and safety are non-negotiable, shock testing is a vital part of validation and compliance. From electronics and EV batteries to aerospace structures and consumer packaging, a shock test system ensures products can survive the real world.

But how do you select the right shock test equipment for your unique needs? This guide breaks it down—with examples from different industries—to help you choose confidently.

What Is a Shock Test System?

A shock test system simulates sudden mechanical forces—like drops, collisions, or impacts—to assess a product's resistance to mechanical stress. These systems generate controlled shock pulses (half-sine, trapezoidal, sawtooth, or SRS) with varying acceleration levels (measured in Gs) and durations.

How to Choose the Right Shock Test System

Here’s a clear 4-step framework to guide your selection.

1. Understand Your Product and Application

📦 Packaging & Logistics Industry

Goal: Simulate drop, incline, or impact scenarios during shipping.

Drop Test Machine (ISTA/ASTM certified)

Incline Impact Tester

Mechanical Shock Tester

✅ Example: A company testing corrugated boxes for e-commerce uses an ISTA 3E-compliant drop tester with corner and edge drop capability.

🚗 Automotive & EV Battery Industry

Goal: Validate battery packs, sensors, or control units under crash-like shock.

Air-driven mechanical shock systems (UN 38.3, QC/T 744)

SRS shock testers with modular design

Integration with thermal/vibration chambers

✅ Example: An EV manufacturer simulates a 5,000g SRS profile using TMC’s HSRS800 to certify lithium-ion battery safety.

📱 Consumer Electronics & Semiconductors

Goal: Test PCB assemblies, sensors, or microchips for handling damage or SRS reliability.

Recommended:

Electrodynamic SRS testers for precision

High-frequency spectrum (up to 10,000Hz)

✅ Example: A smartphone supplier uses a TMC system to apply functional shock tests to its PCBs before final assembly.

✈️ Aerospace & Defense Industry

Goal: Certify components to survive launch or airborne shock loads.

Hydraulic or pneumatic shock testers for high payloads

Custom waveform shaping & long-duration shock

✅ Example: A satellite component is tested using TMC’s hydraulic system with sawtooth waveform up to 6,000g at 20ms.

Read also Advancing Defense Testing with TMC Shock Systems

2. Match Required Shock Parameters

| Parameters | Considerations |

|---|---|

| G-levels | Ranges from 50g to 10,000g (industry dependent) |

| Pulse duration | Short (< 5ms) to long (> 20ms) depending on material behavior |

| Waveform types | Half-sine, trapezoidal, sawtooth, SRS |

| Load capacity | From small electronics (5kg) to full battery packs (200kg+) |

| Frequency response | 50 Hz to 10,000 Hz for SRS |

3. Align with Testing Standards

| Industry | Common Standards |

|---|---|

| Packaging | ISTA 3E, ASTM D5276, ASTM D880 |

| Automotive/EV | UN 38.3, GB/T 31485, QC/T 744 |

| Electronics | IEC 60068-2-27, MIL-STD-883 |

| Aerospace | MIL-STD-810G, NASA-STD-7001, RTCA DO-160 |

4. Decide on Integration and Budget

R&D or Production Testing?

Choose manual testers for lab use or fully automated systems for production lines.Modularity & Upgradability

TMC’s air-driven systems are modular, with compact footprints and easy upgrades.Do You Need Combined Testing?

Combine shock with vibration and thermal testing for full environmental simulation.

Why TMC Shock Test Systems?

TMC Systems are built for accuracy, ease of maintenance, and customization. Trusted by global manufacturers, we offer:

📌 Up to 10,000g SRS capability (contact us for customizable solutions)

📌 Compact, explosion-proof air-driven designs

📌 Integration with vibration and climatic chambers

📌 Compliant with global safety standards

📌 Modular upgrades for growing test demands

📞 Need Help Choosing?

Every product has a story—and every test system must be tailored to it. Whether you’re testing consumer goods, EV batteries, or aerospace components, our team will help you choose the system that fits.

➡️ Contact us for a custom consultation.