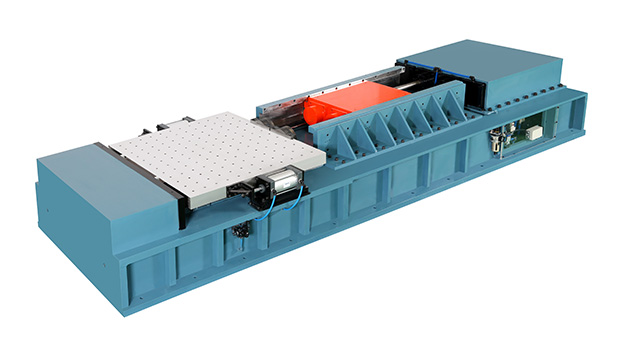

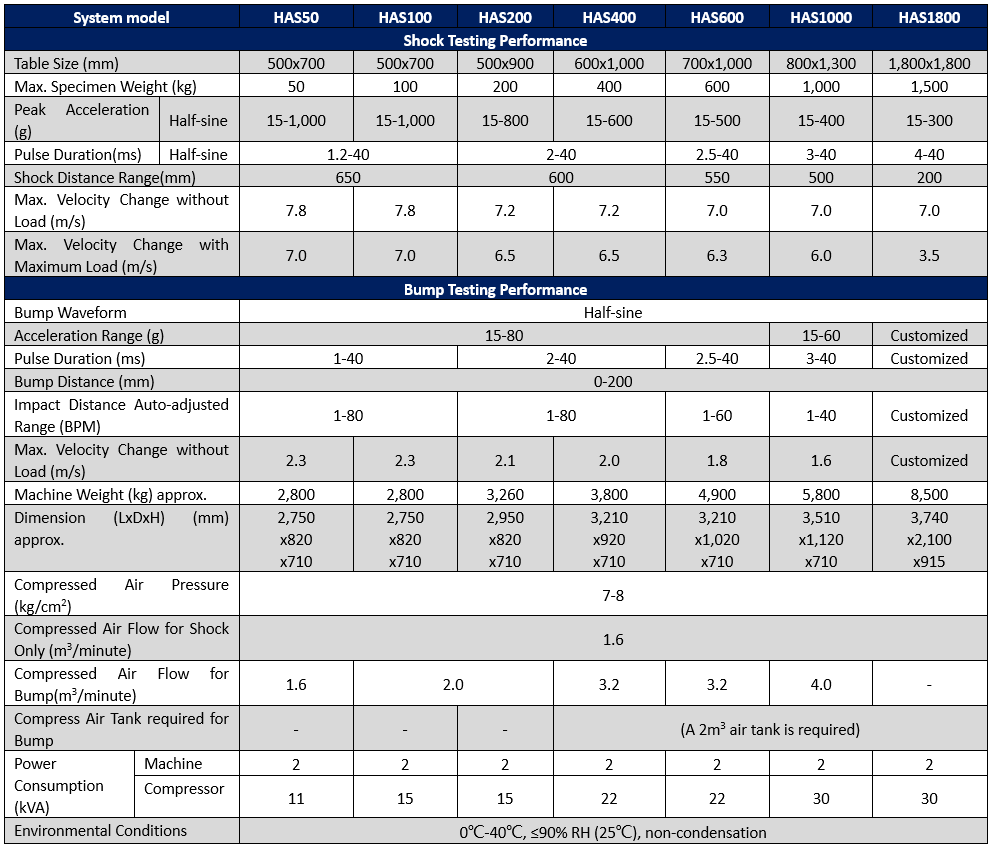

MS series shock testing equipment is used to test the product’s or packaging’s resistance to shock. MS series shock test machine can be used for the shock test of conventional half-sine wave, postpeak sawtooth wave and trapezoidal wave etc, to find out the shock wave and enegry that may be suffered by the product in real environment, and in this way we can improve or optimize the product packaging structure systematically.

System overwiew

● MS series environmental testing machines based on windows operating system are fully-automatic and have friendly control interface. You only need to input the testing data in the operator, the system will automatically configure the parameters and control the machine, then complete the shock test precisely.

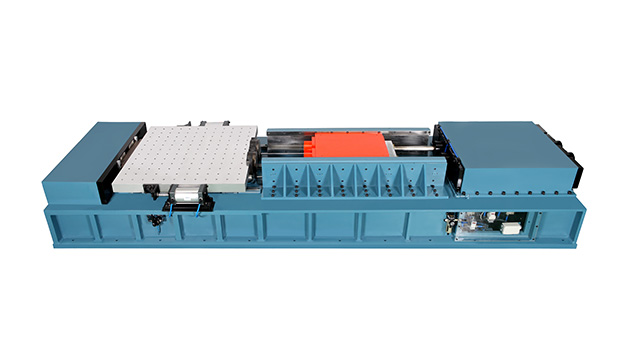

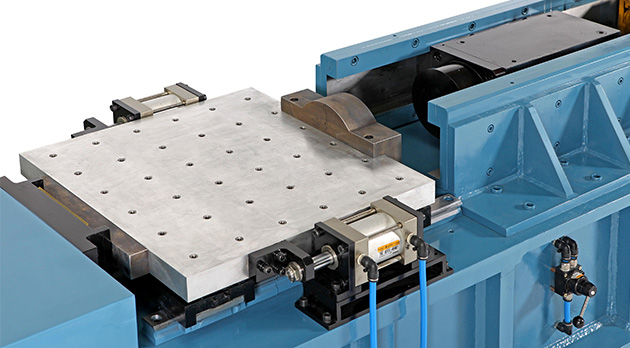

● MS series shock testing equipment has anti-secondary shock brake device. Shock table falls freely to the shock wave-shaped cushion, the hydraulic brake stops the movement of the piston after a rebound, then the shock table is braked and will not shock for a second time.

● Damping device is with high efficiency. When the shock is performed on a big shock test machine, the instant shock force will be very strong. However, a damping device can greatly reduce the shock to the ground. Therefore, the foundation is not needed and the machine is easy to install.

● The shock height is set digitally, so the shock table is automatically lifted to the set height with high control accuracy and good repeatability of the shock data.

● The shock height is set digitally, so the shock table is automatically lifted to the set height with high control accuracy and good repeatability of the shock data.

● Configured shock measurement system displays the data of shock force and waveshape instantaneously.

● High acceleration generator can be configured. When testing small specimen, the shock testing equipment should be with high acceleration. Therefore, you can fix the high acceleration generator on the table of the shock test machine, the shock acceleration can be higher than the normal IS series shock machines according to the shock kinetic energy transfer theory. When the test specimens are smaller than 200 x 200mm, the peak of shock acceleration can be up to 5000-50000 m/s and acceleration can last for 0.2-1ms.